Ọdịmma 316 & 316L igwe anaghị agba nchara na-enye

Xinjing bụ onye nrụpụta ahịrị zuru oke, onye na-echekwa ngwaahịa na ebe ọrụ maka igwe igwe anaghị agba nchara na-ekpo ọkụ na-ekpo ọkụ, mpempe akwụkwọ na efere, ihe karịrị afọ 20.A na-eji igwe igwe igwe 20 na-atụgharị oyi, na-ezute ụkpụrụ mba ụwa, nkenke zuru oke na flatness na akụkụ anyị smart na nkenke ịkpụ & slitting ọrụ nwere ike izute dị iche iche na-achọ, ebe ọtụtụ ndị ọkachamara nka ndụmọdụ na-mgbe avaliable.

Alloy 316/316L austenitic igwe anaghị agba nchara mepụtara na-enye mma corrosion iguzogide Alloy 304/304L, na corrosion arụmọrụ nke SS 304 ezughị, 316/316L na-emekarị tụlee dị ka nke mbụ ọzọ.Ọdịnaya Nickel dị elu dị na 316 na 316L karịa SS 304 yana mgbakwunye Molybdenum na 316 na 316L na-enye ya ihu na arụmọrụ na gburugburu ihe na-emebi emebi na oke okpomọkụ.A na-ejikarị ya eme ihe na iyi usoro nwere chlorides ma ọ bụ halides.Mgbakwunye nke molybdenum na-eme ka corrosion izugbe na nguzogide chloride pitting.Ọ na-enyekwa ihe mgbawa dị elu, mgbakasị ike na mgbawa ike na okpomọkụ dị elu.

"Ihe dị iche n'etiti 316 na 316L akara ule bụ nke ukwu nke carbon ẹdude. The L na-anọchi anya obere carbon, ma L akara ule nwere a kacha 0.03% carbon, mgbe ọkọlọtọ akara ule nwere ike ịgụnye ruo 0.07% carbon. N'ọtụtụ ọnọdụ, corrosion eguzogide nke Alloys 316 na 316L gburugburu ebe obibi corrosive ga-ruru nhata corrosive gburugburu. ive na-eme ka intergranular corrosion nke welds na okpomọkụ metụtara zones Alloy 316L kwesịrị iji n'ihi na ya ala carbon ọdịnaya.

Njirimara ngwaahịa

- Igwe anaghị agba nchara 316/316L na-eguzogide corrosion ikuku, yana oxidizing na-ebelata ma belata gburugburu.

- guzogide corrosion na emetọọ

- ikuku mmiri.

- 316/316L na-abụghị magnetik na annealed ọnọdụ, ma nwere ike ịghọ ubé magnetik n'ihi oyi na-arụ ọrụ ma ọ bụ ịgbado ọkụ.

- Igwe anaghị agba nchara 316/316L bụ enweghị ike isi ike site na ọgwụgwọ okpomọkụ ma nwee ike guzobe ya ma dọpụta ya ngwa ngwa.

- Mgbawa na ike nkwụsị na oke okpomọkụ

- Enwere ike ịgbado ma hazie ya n'ụzọ dị mfe site na usoro nrụpụta ụlọ ahịa ọkọlọtọ.

Ngwa

- Chemical na Petrochemical Processing - nrụgide arịa, tankị, okpomọkụ

- Akụrụngwa ejizi nri na nhazi: ngwa nri, ngwa nri, igwe mmiri ara ehi, tankị nchekwa nri, ite kọfị, wdg.

- Sistemụ iyuzucha ụgbọ ala: Ọkpụkpọ ọkpọkọ na-agbanwe agbanwe, ihe mkpofu ọkụ, wdg.

- Mmiri mmiri

- Ọgwụ

- Nnụcha mmanụ ala

- Nhazi ọgwụ

- Ike Ọgbọ - nuklia

- Pulp na akwụkwọ

- Akwa akwa

- Ọgwụgwọ mmiri

Nhọrọ nke ụdị igwe anaghị agba nchara kwesịrị ịtụle isi ihe ndị a: arịrịọ ọdịdị, ikuku ikuku na ụzọ nhicha nke a ga-anabata, wee buru n'uche ihe ndị achọrọ nke ọnụ ahịa, ọkọlọtọ aesthetics, nguzogide corrosion, wdg, 304 igwe anaghị agba nchara na-arụ ọrụ mara mma na gburugburu ime ụlọ akọrọ.

Ọrụ ndị ọzọ

Ịgbawa eriri igwe

Na-egbutu eriri igwe anaghị agba nchara n'ime ibe obosara pere mpe

Ike:

Ihe ọkpụrụkpụ: 0.03mm-3.0mm

Min/Max obosara mgbawa: 10mm-1500mm

Nkwenye obosara nke ibeji: ± 0.2mm

Na nhazi ọkwa

Igwe mmiri na-egbutu ogologo

Ịcha eriri igwe n'ime mpempe akwụkwọ na ogologo arịrịọ

Ike:

Ihe ọkpụrụkpụ: 0.03mm-3.0mm

Min/Max ịkpụ ogologo: 10mm-1500mm

Mbelata ndidi ogologo: ± 2mm

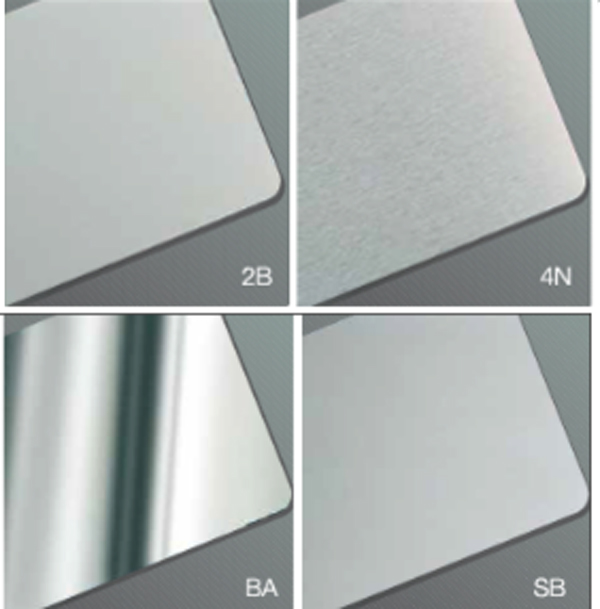

Ọgwụgwọ elu

Maka nzube nke ihe eji achọ mma

No.4, Ntutu ntutu, na-edozi ọgwụgwọ

E mechachara elu ga-echebe site na ihe nkiri PVC